Noya, an American cleantech company founded in 2020, works on Direct Air Capture (DAC) technology to remove excess carbon dioxide (CO₂) from the atmosphere. The company retrofits existing pieces of industrial cooling towers and turns them into CO₂ capture machines, radically reducing the upfront capital costs and installation time required for direct air capture technology.

Challenges: Carbon removal

Carbon removal is the process of permanently sequestering carbon dioxide (CO₂) from the atmosphere. It is essential to prevent the worst impacts of climate change and limit the increase in temperature to 1.5 ºC as outlined in the Paris Agreement.

Different methods for removing CO₂ have distinct advantages and disadvantages, with nature-based methods such as tree planting and forest restoration being the most widely used today. However, the carbon can be released back into the atmosphere when the plants die or burn, so these solutions are likely to have a shorter lifespan.

Technological carbon removal methods include carbon capture and storage (CCS), which involves capturing CO₂ from emission sources such as coal-burning power plants and converting it to other products, storing it, or burying it. Direct air capture (DAC) is another technological approach that involves removing CO₂ from the atmosphere and sequestering it underground.

Direct Air Capture CO2

Direct Air Capture (DAC) technology has several advantages. One of the biggest benefits of DAC is its siting flexibility, as it does not require arable land, thereby minimizing food impacts. DAC can be employed in a wide variety of locations and requires a smaller footprint. It is also location-independent, as CO₂ is in the air at the same concentration (0.04% or 412 ppm) everywhere in the world, making DAC highly scalable and measurable.

However, despite its benefits and flexibility, DAC is more costly per ton of CO₂ removed than many mitigation approaches and natural climate solutions, as separating dilute CO₂ from ambient air is energy-intensive. Today, the range of costs for DAC varies between $250 and $600.

Noya Technology

Noya has developed a unique DAC technology that combines the existing pieces of industrial cooling towers with solid CO₂ sorbents. This transforms industrial cooling towers into CO₂ capture machines, which radically reduces the upfront capital costs and installation time required to perform direct air capture. Therefore, Noya’s approach to DAC will enable them to scale quickly and provide low-priced carbon removal in the near-term.

Why does Noya use cooling towers?

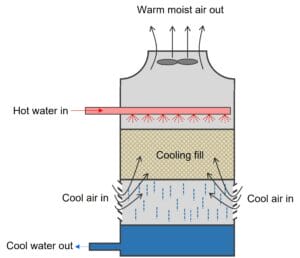

A cooling tower is a tall structure that exposes hot water to air in order to cool and evaporate it. Cooling towers remove heat from process water by evaporation and latent heat. In other words, the cooling tower is a specialized heat exchanger that brings air and water into direct contact in order to lower the temperature of the water. There are more than 2 million cooling towers in the United States.

As depicted in the diagram below, the hot water from an industrial process is pumped to the cooling tower through pipes. The water is sprayed through nozzles onto banks of cooling fill, which slows the flow of water through the cooling tower. Maximum air-water contact is achieved by exposing as much water surface area as possible with the cooling fill. As water flows through the cooling tower, it comes into contact with air. When the water and air come into contact, a small amount of water is evaporated, producing a cooling effect. The air is pulled through the tower by the electric motor-driven fan on top of the cooling tower.

Noya uses cooling towers to provide the energy necessary to move air through sorbents that extract CO₂ from the air, thereby eliminating the need for mechanical devices to drive air flow for CO₂ capture, as is the case with the majority of other companies in this industry.

Noya Direct Air Capture technology

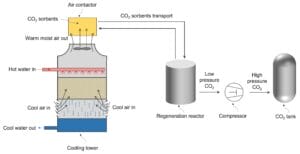

The diagram below depicts the overall system of Noya’s DAC technology.

The system comprises a cooling tower, an air contactor that captures CO₂, a regeneration reactor, sensors and monitors, a compressor, and a CO₂ tank.

- Air contactor

The air contactor can be attached to the cooling tower’s top or an air inlet.

The air contactor contains at least 35 kg of solid CO₂ sorbents. The capacity of the sorbent for CO₂ ranges between 0.1 mmol/g and 1.2 mmol/g. The sorbent has a structure of monoliths, foam, laminate, or fabric, which provides faster mass transfer kinetics, shorter diffusion path, easier heat transfer in all directions, and more uniform temperature distribution in comparison to beads, pellets, or power sorbent.

The sorbent comprises at least one of magnesium oxide (MgO) aerogel and aluminum oxide (Al₂O₃). These materials are sinterable, stable, resistant to moisture, easy to control, porous, inexpensive, and formable. The sorbents may contain other materials, such as potassium carbonate (K₂CO₃) and activated carbon. The CO₂ capture rate of the sorbent is between 0.01 to and 2 mmol/min/g of sorbent.

- Regeneration reactor

The regeneration reactor releases the captured CO₂ by heating the CO₂-saturated solid sorbent from the contactor to a sufficient temperature between 80 ºC and 600 ºC for about 15 minutes to about 200 minutes for the sorbent to release the CO₂.

Noya’s solid CO₂ sorbent requires less thermal energy input to liberate CO₂. This reduces process operational costs. In addition, the regeneration reactor has a chamber that creates and sustains a vacuum environment to facilitate CO₂ release. The reactor can be powered by renewable electricity.

- Sensors and monitors

The CO₂ sensors monitor the absorption rate and allow the system to determine an amount of CO₂ likely captured by the sorbent. Based on the determination, the sorbent may be transported to the regeneration reactor.

How does Noya Direct Air Capture technology work?

A cooling tower provides the flow of air through the air contactor which contains solid CO₂ sorbents. The sorbent captures CO₂ from the air. The CO₂-saturated sorbent is then transported to a regeneration reactor. Under high temperature and vacuum, the captured CO₂ is released from sorbent in the regeneration reactor. The regenerated sorbent is transported back to the air contactor. The released high-purity CO₂ is pressurized to a liquefaction pressure of about 800 psi and then stored in a CO₂ tank.

As the sorbent particles are transported between the air contactor and the regeneration reactor, the sorbent is subjected to wear and abrasive forces over time. When the particle size of the solid sorbent is smaller (due to attrition) than the absorption container’s “permeable” holes, the sorbent is replaced. When the solid sorbent is formed into pellets, it can be reground and sintered to achieve the desired shape and size.

Noya Patent

- US20230036635A1 Systems and methods for capturing carbon dioxide

Noya Technology Applications

CO2 removal projects

Noya’s technology is designed to be scalable and cost-effective, with a modular design that can be powered by renewable energy. Each module is designed to remove approximately 60 tons of CO₂ annually from the atmosphere.

Noya Products

The market for Direct Air Capture technology is growing rapidly, and it is expected to reach $6.86 billion by 2029 with a CAGR ( Compound Annual Growth Rate).

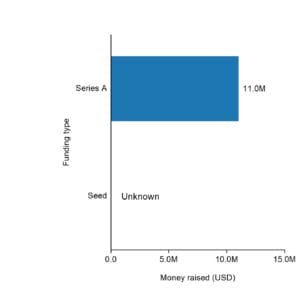

In April 2023, Noya received a $11 million Series A round investment to accelerate the release of their first commercial pilot.

Noya plans to launch its first testing facility in 2024. This facility is expected to remove about 350 tons of CO₂ annually.

Noya Funding

Noya has raised a total of $11M in funding over 3 rounds:

Their latest funding was raised on Apr 11, 2023 from a Series A round.

.

Noya Investors

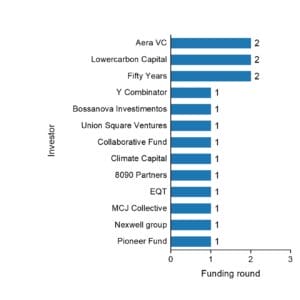

Noya is funded by 12 investors, including

- Y Combinator

- Lowercarbon Capital

- Fifty Years

- Bossanova Investimentos

- Union Square Ventures

- Collaborative Fund

- Climate Capital

- Aera VC

- 8090 Partners

- EQT

- MCJ Collective

- Nexwell group

EQT and Lowercarbon Capital are the most recent investors.

Noya Founder

Josh Santos and Daniel Cavero are Co-Founder.

Noya CEO

Josh Santos is CEO.

Noya Board Member and Advisor

Fred Wilson and Sophie Bakalar are Board Member.